A scheduled or unscheduled repair or maintenance is to be performed. Now what? Everything must be ready as quickly as possible, so that you can sail again as soon as possible. After all, every day in dry dock and every delay cost a great deal of money. It is our observation that proper preparation for the work to be performed can significantly shorten the elapsed repair time. Proper preparation enables our technicians to get down to work quickly and safely. This blog contains questions you must be able to answer for our Service Department and 8 tips to prepare for the arrival of a service engineer.

Ensure you have good and complete information in advance

If you wish to schedule maintenance or repair, contact our Service Department well ahead of time to ensure that a technician is available at the right time. In the run-up to the work, the current condition and model of the seal must be identified as well as possible so that the technician is well prepared before getting down to work.

This is why it is important for you to have the answers to the following questions:

What is the seal's serial number?

This number generally starts with an X or a B and enables us to track down the seal’s structure and its maintenance history with Lagersmit. Serial number for the rear seal unavailable? No problem, we can probably retrieve this information on the basis of the following details:

- Ship’s name or previous names, if any

- IMO code

- Serial number of the forward seal

What is the nature of any leakage?

All worn-out parts are replaced by default as part of regular maintenance. However, if the focus is on repairing a leak, then it is important to know the nature of the leakage. The following information is useful in this respect:

- Which tank(s) are affected by the leak? Which tanks are rising and which ones are dropping?

- What is the magnitude of the oil loss per unit of time?

- When did the oil loss first occur?

The job can be started once the right information is available. During the work itself you can also do a number of things to allow the job to proceed smoothly and therefore economically. Our Service Department therefore prepared:

8 tips for a scheduled service job

Aft seal

1. Install a scaffold on which our technician can work safely

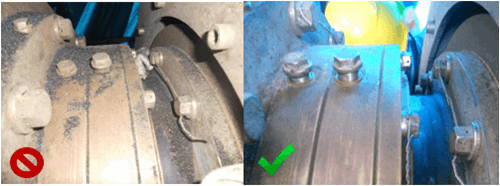

2. Have the shipyard remove the rope guard and carefully spray the outside of the seal box clean

3. In case of regular maintenance, the shipyard can drain the sleeve in advance

4. To be able to mount the seals in situ, the technician requires 230V on the scaffold

Finally, naturally you will want to keep the new seals clean. For this reason make sure that no other work that causes dust is being performed in the vicinity. For example spraying, sandblasting, grinding and welding work. Preferably schedule these activities prior to the installation of the new seals.

Forward seal

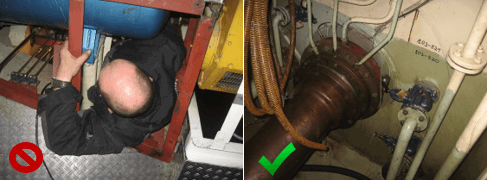

5. Make sure that the seal can easily be reached by our technician. Ample space is required for the technician, as well as the tools. This is the only way to achieve an optimal result.

6. Remove any floor plates and sections. At the same time, make it possible to disassemble them for future maintenance

7. Give due consideration to draining the small tanks and the sleeve. Make sure that everything is clean

8. Provide for a 230V cable near the seal

Cost savings due to proper planning

With proper preparation your work here is half done. Proper planning combined with proper preparation saves money. Experience shows that in some cases proper planning can result in cost savings of up to 30%!

If you would like to engage our service engineers to support and assist you during your upcoming maintenance, we are there for you! Lagersmit provides 24/7 support with its global network.