In our blog “Arranging extra protection for your seals (1): wire winders and net cutters” we mentioned that there are several options to enhance and customise your seal. In this blog we highlight two more options that can be applied to lengthen the lifetime of your seal, specifically the liner: the divisible Distance Ring and the liner applied with a hard metal layer (HML). With the help of a divisible Distance Ring, which can be removed during maintenance, it is possible to reposition the entire seal to create a new clean running surface for your lip seals. HML is a special hard metal layer to improve the wear resistance of the liner. Find out more about how these options can deliver peace of mind to you!

Distance ring

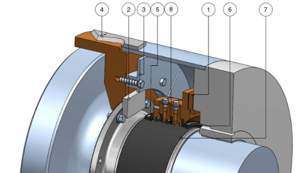

Most liners are made out of chrome steel for its corrosion resistance in seawater. Eventually the lip seals will create grooves in the liner. When these grooves become too deep, leakage can occur. Then the liner outer diameter can be re-machined to create a new running surface for the lip seals. There is however a minimal outer diameter to which the liner can be machined, without compromising the functioning of the seal. To lengthen the chrome steel liner’s service life a Distance Ring is often used (picture 1, position 1). The divisible Distance Ring can be removed during maintenance, after which the complete seal housing can be shifted, enabling a clean liner running surface for the lip seals. This way there is no need to pull the shaft or remove the propeller hub. When the vessel is due for docking again it could become clear that the liner needs machining. Note that the Distance Ring can be reinstalled to gain an even longer lifespan.

Hard Metal Liner coating

Seal manufacturers have always tried to lengthen the lifetime of the liner, using alternative types of chrome steel and coatings such as ceramics. Lagersmit provides the option to use a liner with an HML (picture 1, position 7). To apply this layer on the liner a production process, called HVOF spraying, is used. Under strictly controlled production conditions a very hard layer is formed with a high adhesive strength and a porosity of less than 1%, preventing crevice corrosion, which can occur on ceramic layers.

Compared to ceramic coatings, the HML has a better heat transfer. This prevents ageing of the lip seals and lengthens the life of the seal as a whole. The liner with HML does not need re-machining, because the lip seals won’t create grooves in the liner and therefore pulling the shaft or removing the propeller hub for this sole purpose is history. The HML can be applied on all our non-split chrome steel liners.

The life of a liner may be extended up to 20 years depending on the specific operating conditions of the Supreme® seal. Customer experiences show that after 5–10 years of operation, the HML coated liners show virtually no wear.

Dirt barrier and cathodic protection

Would you like to avoid damage to the aft seal caused by sand and debris? Or do you need to ensure improved corrosion protection on your liner with extra anodes? Find out how these options will deliver you Peace of Mind at our customised options overview.