We have been a trusted supplier of shaft seals for industrial and dredge pumps for decades. The water-lubricated Liquidyne® seal was in 1983 initially developed for heavy-duty dredge pumps that work under harsh conditions with lots of sand and vibrations. For a reliable operation, it's crucial to prevent sudden pump failure. Pump shaft seal failure and leakage is one of the most common reasons for pump downtime. Most leaks in pumps are caused by a change of operating conditions such as wear, vibration and varying pressure of the pump media. The Liquidyne easily adapts to the operating conditions thanks to its robust design.

How the Liquidyne works

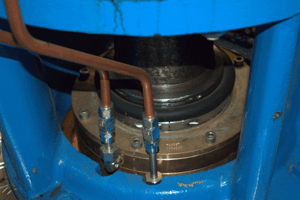

The water-lubricated lip seals run over a partially grooved bush which is placed over the pump shaft. The helical shape of the grooves and peripheral speed (RPM) of the bush creates water flow (similar to aquaplaning) between the grooves and the lip seal. The water flows from the pump side to the drain of the seal. The condition of the seal is monitored by measuring the water flow from the pump side to the drain of the seal. The different modules of the lip seals ensure the sealing of the pump shaft, reducing pressure and retaining dirt.

The evolution of the Liquidyne

During the past years, we haven't stood still and constantly developed the Liquidyne. Condition monitoring has been one of the biggest advantages of the Liquidyne for a long time. Condition monitoring predicts the lifetime of the seal and minimises the risk of sudden pump failure. Over time, the grooves on the bush gradually wear down. Less water is transported over the bush and the amount of water leaving the drain decreases. Previously, the lifetime of the seal was manually measured with a bucket and the amount of water that was transported over the bush.

Nowadays we offer fully digital flow meters to measure the flow rate of fluids. By installing the flow meters in the pumps pipeline, the rate can be measured without disturbing the flow of fluids. The collected data can be recorded locally at the pump site or in a digital data management (PLC) system.

The smart seal

Thanks to the digital flow meter, we have a smart seal that realises condition monitoring for industry 4.0. The pressure, flow and temperature can be measured by the condition monitoring function. The pressure is measured at multiple places in the pump to compare the pressure differences. In this way the pressures can be compared with the pressure (positive or negative) at the seal.

The collected data is read out for analysis and combined for practical insights about the seal. The trendline that arises provides the predicted lifetime of the seal. Possible leaks can be prevented by varying with the pressure on the seal and flow rate. It's important that pressure is measured at multiple places in the pump. The lifetime of the pump shaft seal can be extended even further by cleverly compensating for these pressures.

Several innovative customers are already busy with industry 4.0 and have discovered the benefits of our smart Liquidyne pump shaft seal. Do you want more information about the Liquidyne or condition monitoring? Contact us or visit our stand during an exhibition!