LIQUIDYNE® PUMP SHAFT SEALS

ABOUT LIQUIDYNE®

PUMP SHAFT SEALS

The Liquidyne pump shaft seals are the alternative to gland packing and mechanical seals. The Liquidyne has a predictable lifetime due to the condition monitoring function. In addition, the pump shaft seal is also environmentally friendly thanks to the water-lubricated system that saves energy through reduced friction on the shaft.

Released in 1983, the water-lubricated Liquidyne pump shaft seal was initially intended for heavy-duty dredge pumps. Thanks to its robust design, the seal can handle above-average axial and radial play. It is suitable for pumps that have to deal with severe shocks and vibrations, incorrect alignment and abrasive media. The Liquidyne increases the pump’s lifetime and leads to a longer mean time between maintenance (MTBM) thanks to its robustness. Condition monitoring adds predictability and makes your operation more secure.

HOW IT WORKS

The (water) lubricated lip seals run over a partially grooved bush placed over the pump shaft. The helical shape of the grooves and peripheral velocity of the bush create water flow between the grooves and the lip seal.

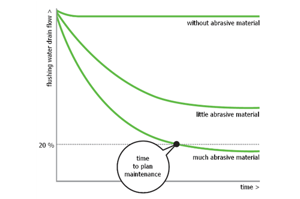

PREDICTABLE LIFETIME

One of the main benefits of the Liquidyne is that the condition monitoring function is not just to simply monitor the condition of the seal, but it also creates a predictable lifetime. How? Over time, the grooves on the bush gradually wear down. Less water is transported over the bush and the amount of water leaving the drain decreases. When the drain flow is at 20% of the initial flow, maintenance needs to be planned.

By keeping track of this drain flow you can plan maintenance more efficiently, minimising the risk of sudden pump failure, optimise mean time between maintenance and reduce costs.

PRODUCTS

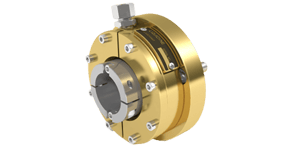

Targeted design for dredging and slurry pumps

Read More about the liquidyne 3-stage WA

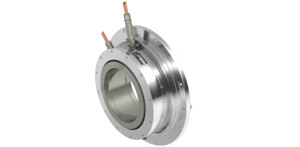

Standard design for pumps that process relatively clean media

Read More about the liquidyne 2-stage

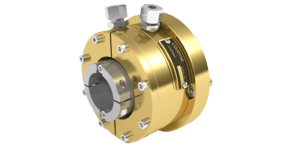

Specially designed for pumps that process polluted and aggressive media

Read More about the liquidyne lds

.jpg?width=200&name=logo-berg-propulsion%20(1).jpg)