ROTARY SHAFT SEALS

TABLE OF CONTENTS

ROTARY SHAFT SEALS

Rotary shaft seals are used to protect installations with a rotating shaft in wet environments. The rotary shaft seals keeps lubricant (oil, grease or water) inside the application and prevents the ingress of water and dirt. Our sealing systems protects thousands ships, pumps and tidal turbines against fluids.

APPLICATIONS WITH ROTARY SHAFT SEALS

A number of applications that use rotary shaft seals to prevent the leakage of fluids:

Propulsion systems at all kind of vessels, like cargo, ferries and superyachts

Centrifugal pumps on dredging vessels

Process pumps at industrial companies

Submerged tidal turbines

Pumping stations for water control

You could use outdated gland packing or mechanical seals for your rotating shaft, but at Lagersmit we rely on rubber lip seals. Rubber lip seals are an essential element in the design of rotary shaft seals at Lagersmit for decades. The two most important functions of rotary shaft seals are:

Prevent water, dirt and dust from entering the installation

Prevent fluids (usually oil or grease) from leaking out of the installation and ending up in the environment

HOW DOES A ROTARY SHAFT SEAL WORK?

Lip seals at rotary shafts work with a small contact area on the liner, which in turn is placed around the shaft. A garter spring ensures a constant force of lip seals on the shaft. The seal works due to a hydrodynamic lubricating film between the lip seal and its counter surface. This area is called the sealing gap and the film thickness, in general, is a few microns. The lubricating film is most stable between two flattened surfaces, therefore over time, the lip seals tip will slowly wear to a small sealing surface.

Advantages of using lip seals:

Low frictionMinimal heat development

High-pressure compensation

Reduced energy consumption

Effective separation of water and lubricants

LIP SEAL MATERIAL

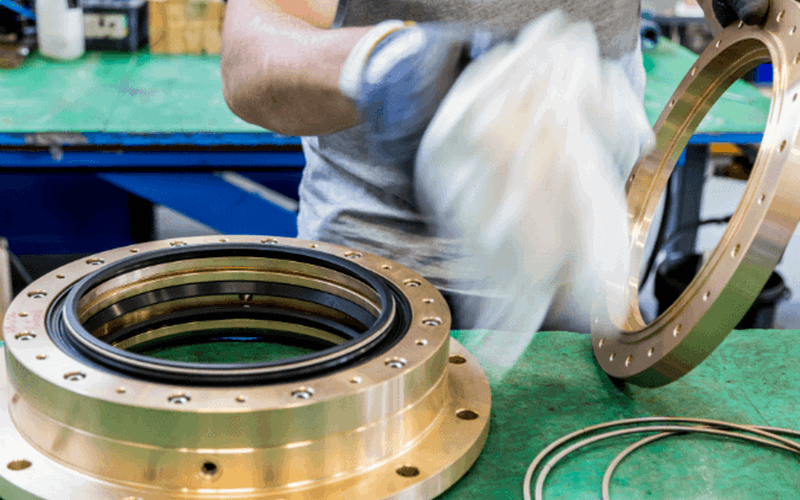

Our rotating shaft seals are build-up with NBR, FKM or FKM-EAL lip seals, Hastelloy® C4 springs, liners, gaskets, O-rings and housing parts like metal rings. All our sealing solutions for rotating equipment contain two up to five lip seals to ensure a reliable operation. The required number of lip seals depends on the application and environment. Some form a barrier against water ingress and another to prevent lubricant leakage into the environment.

HOW TO SELECT THE RIGHT ROTARY SHAFT SEAL?

There are five important things to keep in mind when selecting a rotary shaft seal.

- The environment of your application, like salt or sweet water

- Operating conditions like RPM, pressure and temperature

- Lubrication type (mineral / eal oil, grease or water) that is used

- Selecting powerful options like dirt barrier and hard metal liner (HML) coating

- The requirement of extra safety with an additional lip seal

Get in touch with us to get specialist advice for your application.

REPAIR & REPLACEMENT OF ROTARY SHAFT SEALS

Shaft seal failure and leakage can be caused by several things, but it mostly results in worn-down rubber lip seals. For every shaft seal, there’s a unique service kit to replace the soft wearable parts. Do you need help with the installation? We’ve worldwide available and certified service engineers who can among others assist you with the installation, repair and replacement of shaft seals. Besides that, our engineering manuals can also help you through the process of installation the spare parts on your application.