The habitability and the quality of life in the Netherlands is determined to a large extent by the protection of dunes and dikes, and water management. On the one hand there is a need to counteract the dangers of high waters and on the other hand it is necessary to keep the land behind the dikes dry. A large part of the Netherlands is located below sea level. The discharge of water consequently is very important. For this reason it is extremely important to prevent the sudden failure of pumping stations. Now imagine that it is possible to create a predictable operation.

Vier noorder koggen pumping station

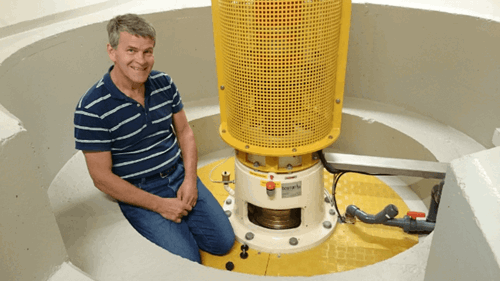

The Vier Noorder Koggen pumping station, located in Onderdijk in the Province of Noord-Holland, is the very best there is in terms of innovative pumping stations. This pumping station was recently completely renovated, says Mr Leo Broers, Manager Water-level Control Works at the Hollands Noorderkwartier Water Authority. The renovation has increased the pumping station’s capacity. Calculations show that downpours are becoming more severe and that water levels will rise.

After the renovation, the pumps at the Vier Noorder Koggen pumping station will be able to pump 1,400 cubic metres of water into the IJsselmeer every minute. Leo Broers: “That’s 1.4 kilometres of water 1 metre high and 1 metre wide in one minute!” Previously this was 1,140 cubic metres of water per minute. At that time the pumping station had two diesel motors and two electrically driven motors.

During the renovation an assessment was also conducted to determine how to reduce the pumping station’s failure causes. Each day, hundreds of employees at the Hollands Noorderkwartier Water Authority work on protecting the land and the quality of the surface water. Safety and the public interest are a high priority and reducing the failure rate was consequently considered important. For this reason it was decided to replace the pumping station’s diesel motors with electric motors. Currently this is a perceptible trend in the world of pumping stations. This is because the failure rate of electric pumps is lower. The probability of failure at the Vier Noorder Koggen pumping station was reduced even further by upgrading the seals.

How the Liquidyne seal makes the Netherlands safer

During the renovation of the Vier Noorder Koggen pumping station the gland packings were replaced by a Dutch innovation, the Liquidyne® seal. The Liquidyne is a water-lubricated pump seal originally developed for the dredging market. In addition, the seal can signal its condition at any point in time. As a result this seal has an optimal service life, which prevents the standstill of the operation for maintenance and sudden failures.

Leo Broers opted for the Liquidyne after he saw it in operation at the Lijnde pumping station at Haarlemmermeer in the Netherlands. The Liquidyne had been running for 30,000 hours here and still looked as good as new. Combined with the fact that a seal at the Vier Noorder Koggen pumping station is only good for 1,200 operating hours per year, this convinced Broers.

The Liquidyne provides peace of mind at the pumping station due to its:

- optimal service life;

- environmentally friendly operation (water lubrication instead of grease lubrication);

- relatively low power consumption.

This renovation makes the Vier Noorder Koggen pumping station a reliable pumping station that creates a far safer natural and residential living environment. Contact us for more information about this project.