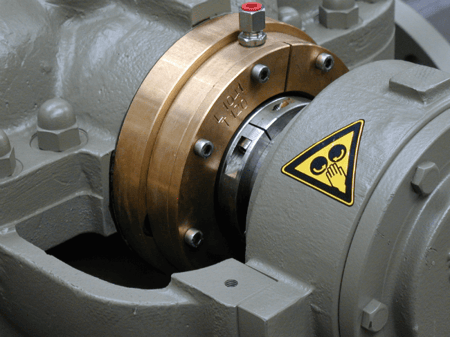

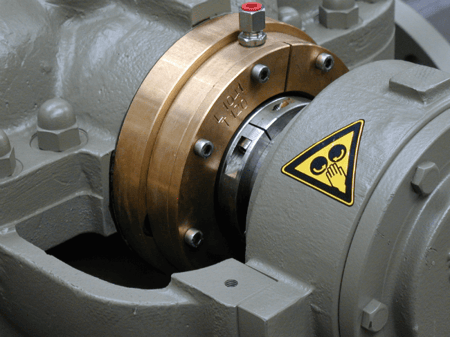

PUMP SHAFT SEALS

TABLE OF CONTENTS

WHY DO YOU NEED TO SEAL YOUR PUMP?

A pump shaft seal works on the rotating shaft were it passes through the non-rotating housing parts. The pump shaft seal allows the rotating shaft to enter the ‘wet’ area of the pump without leaking fluids.

HOW PUMP SHAFT SEALS WORK

The (water) lubricated lip seals run over a partially grooved bush placed over the pump shaft. The helical shape of the grooves and peripheral velocity of the bush create water flow between the grooves and the lip seal.

LIQUIDYNE® PUMP SHAFT SEAL

Predictable lifetime & environmentally friendly

The Liquidyne® pump shaft seal has a predictable lifetime due to the condition monitoring function. It is also environmentally friendly due to the water-lubricated system that saves energy through reduced friction.

Liquidyne pump shaft seals add quality and reliability to your operation and have already been successfully installed in around 10,000 pumps. Lagersmit currently delivers Peace of Mind to a vast range of pump manufacturers, petrochemical and energy companies. Shell, Nouryon Industrial Chemicals (formerly AkzoNobel), Stork and Sabic use the Liquidyne to their full satisfaction.

COMPARISON WITH GLAND PACKING AND MECHANICAL SEAL

Pump shaft seal failure is one of the most common reasons for pump downtime. That’s why you want a reliable pump seal, which ensures optimal operation hours and keeps going. In our blog we compared the Liquidyne to two types of pump seals: gland packing and mechanical seal.

COOLING-WATER PUMP

SABIC BUFA plant

A number of years ago, SABIC and Lagersmit teamed up as part of a Global Framework Agreement. This collaboration started in 2004 with the successful installation of a Liquidyne® seal for a cooling-water pump from SABIC’s BUFA plant.

LIQUIDYNE 3-STAGE

The Liquidyne 3-Stage is especially developed for dredging pumps that process a polluted medium with abrasive media particles that are larger than 100 µm. The Liquidyne seals the pump shaft and uses an external flush to lubricate, cool and clean the seal, while the drain flow enables the condition monitoring.