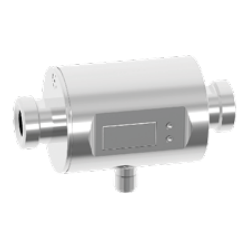

FLOW METER

FLOW METER

Whether it’s a dredging operation or a cooling water process, the work goes on, day and night, worldwide. Lagersmit introduces the next step in ensuring a stable pump operation. With the specially selected digital flow meters, the monitoring of the Liquidyne ® seal and the pump condition becomes very easy.

ADVANTAGES

- Maintenance can be planned and intervals maximized

- Better control and accuracy of flush and drain

- Applicable to all Liquidyne seals

HOW IT WORKS

By installing the non-mechanical flow meter in a pipeline from the pump, the flow is logged without disrupting the flow. The data can be logged in your data management system or locally at the pump site. The state of the shaft sleeve is measured based on the flow. Due to the wear of the grooves on the shaft sleeve, the flow decreases over time. The grooves are flattened and the lip seal will have more contact with the running surface. This allows less water to be transported over the shaft sleeve. The water flow towards the drain decreases and, as a result, the drain flow decreases. If this drain flow is down to 20 % of the initial flow, maintenance is required.