SUPREME® TIDAL GENERATION

TABLE OF CONTENTS

SUPREME® TIDAL GENERATION

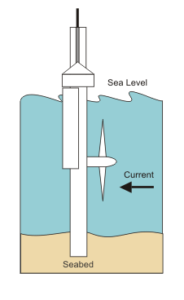

The Supreme Tidal Generation is designed especially for tidal turbines. Through co-engineering, we have developed a tailored sealing solution for many tidal applications.

APPLICATIONS

- Tidal turbines

ADVANTAGES

- Optimized maintenance intervals

- Environmentally friendly

- Fully customised

HOW IT WORKS

Seals in tidal turbines are usually lubricated with water or grease.

WATER LUBRICATION

The water-lubricated system is designed to work under varying water pressures. It uses a water-lubricated system where water is circulated through small channels inside the housing parts. These channels function as an orifice, which decreases the prevailing water pressure to the atmospheric pressure inside the nacelle. The water is then filtered and pumped back to the rotor side.GREASE LUBRICATION

This grease-lubricated system uses multiple lip seals that deliver a high level of redundancy. The grease lubrication system recirculates the grease and effectively minimises grease consumption. The grease refilling period is at least five years.

THE MEYGEN PROJECT

The MeyGen project is the largest planned tidal stream project in the world and is located in Scotland. When the project is finished, 269 tidal turbines will generate enough power for 175,000 houses in Scotland. In August 2017 the MeyGen project has already set a new world record for monthly production from a tidal stream power station and has generated 2,200 MWh of electrical energy.

CUSTOMISATION

Are our standard solutions not suitable for your application? Our engineers are more than happy to develop a custom-made sealing product!