Pump shaft seal failure is one of the most common reasons for pump downtime. That’s why you want a reliable pump seal which ensures optimal operation hours and keeps going. In this blog we compare two types of pump seals: The Liquidyne® seal and the Mechanical seal.

Liquidyne seal

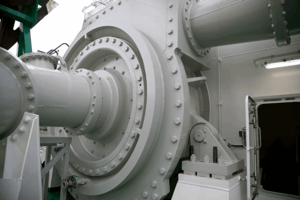

Released in 1983, the Liquidyne pump shaft seal was initially intended for heavy-duty dredge pumps and is the next step for gland packing and the alternative for a mechanical seal. Thanks to its robust design, the seal can handle above-average axial and radial play. It is suitable for pumps that have to deal with severe shocks and vibrations, incorrect alignment, and abrasive media. The Liquidyne increases the pump’s lifetime and leads to a longer mean time between maintenance (MTBM) thanks to its robustness. Condition monitoring adds predictability and secure operation.

Mechanical seal

Mechanical seals are durable and a good choice for long-term of your pumps. They ensure very little fluid leakage and can sustain high pressure and corrosive fluids . Besides this, mechanical seals are more for axial play and more expensive for larger shaft diameters.

Liquidyne vs mechanical seal

The Liquidyne seal is a better alternative to a mechanical seal and offers the following advantages:

Predictable lifetime

The Liquidyne operates while being condition monitored. This feature ensures Peace of Mind, as it allows the operator to observe the trend line of the flow from the drain. It also features a timely notification when the drain flow is at 20% (instead of a sudden failure of a seal), so you can plan maintenance.

Optimised cost of ownership

The Liquidyne is economically attractive because of the possibility to order spare parts. Usual maintenance calls for the whole seal to be replaced – not with the Liquidyne. A typical initial maintenance would involve changing the soft wear parts only. Just imagine the cost savings: using the Liquidyne means you only change the actual wear parts!

Energy consumption is minimised because the seal uses a lubrication film between the lip seals and shaft sleeve, ensuring the lowest possible friction and minimal heat development. Besides spare parts and savings on the energy consumption, the seal is also easy to maintain. The only maintenance required during operation is to check the drain flow from the Liquidyne as a means of condition monitoring, which saves valuable working time for staff.

Robust seal design

Initially developed for heavy-duty dredge pumps, the seal’s robust design plus the use of lip seals means it’s virtually non-sensitive to abrasive media.

The axial positioning on the shaft is no longer a precision job thanks to the lip seals, and air traps, sudden drops or spikes in pressure, and vibrations aren’t a direct reason for the failure of the Liquidyne seal. As the Liquidyne is a radial seal, the positioning on the shaft sleeve is always on point. The Liquidyne seal can handle above-average axial and radial play compared with a mechanical seal.

Main advantages

- Predictable lifetime: condition monitoring minimises the risk of sudden pump failure

- Optimised cost of ownership thanks to option to order spare parts, energy savings, and easy maintenance

- The Liquidyne has a robust seal design, making it virtually non-sensitive for abrasive media