The propulsion of a vessel has a huge impact on the environment. The stern tubes and thrusters are mostly filled with hundreds of litres of oil to ensure lubrication of the shaft.

All this oil is separated from the water with just a few lip seals. In the case of any leakage, the environmental impact will be huge. What if fishing lines damage your seal and cause a propulsion shaft seal leakage in the middle of the ocean?

Conventional propulsion shaft seals always have a small consumption of oil. Oil pollution will take place if you don’t have a sealing system that ensures zero emissions of oil. If you care about the environment, a zero-emissions propulsion shaft seal is a possible solution.

The maritime industry is well on its way to a greener and more sustainable fleet. The main goal is to minimise the environmental impact of all vessels worldwide. The Fleet Transition Plan shows the ambition to reduce carbon intensity of its controlled fleet to 50% by 2030, compared to the level of 2008. Still, if we don’t take more drastic measures, emissions will increase between 50% and 250% by 2050 under a business-as-usual scenario, according to the International Maritime Organization (IMO).

It’s clear that we need to make more changes to ensure a greener fleet, minimising the footprint and being more eco-friendly. How could the propulsion systems of your vessels contribute to reach this goal?

- Modernise your fleet and reduce oil emissions.

- Monitor the condition of your vessels’ propulsion systems to optimise efficiency.

- Use EAL (environmental acceptable lubricant) oil instead of mineral oil.

Modernise your fleet and reduce oil emissions

Lagersmit has initiated and experienced a changing demand from its customers over the years. The transition from conventional propulsion shaft seals to air-type sealing systems is most striking. Ensuring zero emissions of oil is key and has the full attention of shipowners. Lagersmit is fully dedicated to supporting customers with the transition towards a more sustainable fleet, said Jan Willem Bongers, Sales Manager at Lagersmit.

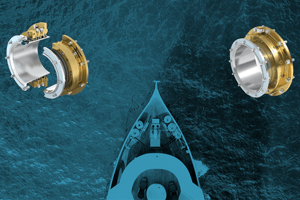

Retrofitting your propulsion shaft seal with our eco-friendly Supreme SeaGuard Ventus® shaft seal has never been easier. Our Supreme SeaGuard Ventus is a proven concept which is already installed on hundreds of vessels worldwide.

As dedicated shaft seal experts, we have developed a powerful solution which guarantees zero emissions of oil. At the same time, this prevents water from mixing with the oil. The Supreme SeaGuard Ventus is an intelligent, durable and self-regulating sealing solution for any type of vessel. A constant air flow prevents an oil-to-water interface and drains any leakage into a monitoring tank. With the Supreme SeaGuard Ventus seal you can continue to sail with mineral oils and ensure zero emissions.

Benefits of the Supreme SeaGuard Ventus sealing system:

- Complies with the VGP and VIDA regulations.

- Avoids the use of expensive bio-oils.

- Extra safety against oil leakage.

- Safe to postpone maintenance.

- 24/7 condition monitoring.

- Zero emissions of oil.

- Low total cost of ownership.

- Five-year warranty (ask for details).

Learn more about our self-regulating sealing solutions.

Monitor the condition of your vessels’ propulsion system to optimise efficiency

Another way to reduce your environmental footprint is to monitor the condition of your seal, by keeping a close eye on the condition of the seal and by intervening in time if things go wrong. This is where you can make the difference in terms of minimising your environmental footprint. The Supreme (SeaGuard) Ventus can monitor several vital functions of the seal and stern tube system.

The importance is obvious: operational feedback prevents surprises and ensures a stable performance of the propulsion system. The Supreme (SeaGuard) Ventus system ensures 24/7 feedback on: bearing clearance, temperatures and oil or water leakage drains into the vessel. This is what we call 100% intelligence.

Use EAL oil

EAL means lubricants that are biodegradable, non-bio accumulative and minimally toxic. Changes, like the Vessel General Permit (VGP) and Vessel Incidental Discharge Act (VIDA), banish all mineral oil-to-water interfaces. If you want to sail with an EAL, you have to check the compatibility of the EAL with the rubber compound of the seal. You can fit your propulsion shaft seal with Supreme FKM EAL lip seals, which are compatible with biodegradable oils.

With more than 160 years of experience in maritime solutions, we’ve seen a change in propulsion shaft seal demand. Multiple customers have already made the switch from mineral oils to EALs to meet the VGP/VIDA requirements. After years of sailing with EALs, customers want to switch back to mineral oils with air-type sealing systems due to performance issues. EALs are more expensive, which has led to a huge increase in total cost of ownership compared to mineral oils. Whether you choose to sail your vessel with EALs or with mineral oils and the air-type sealing systems, Lagersmit is here to help you!

Get in touch for more information about our products or a no-obligation quotation.