IDEA MARINE

RETROFIT FOR AN EXTRAORDINARY VESSEL

RETROFIT FOR AN EXTRAORDINARY VESSEL

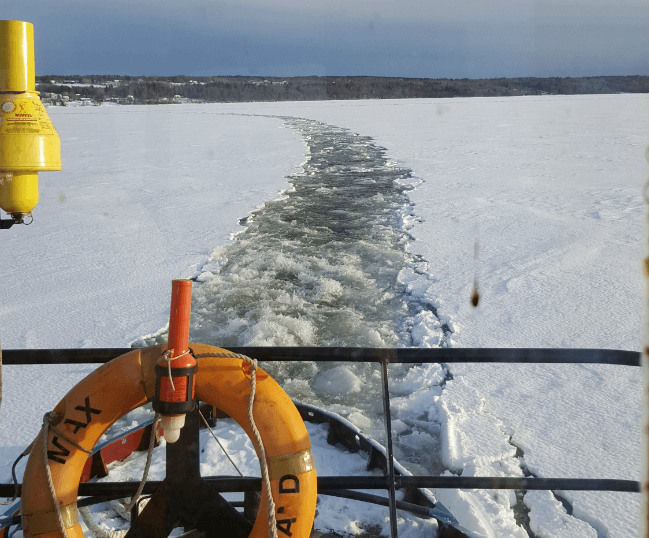

This project involves a retrofit of a vessel called Max, a harbour ice breaker. Max is owned by a privately owned company, Northlands Sea Entrepreneurs, which provides ice-breaking services. Why is this vessel extraordinary? Well, it was built in the 1950s, making it over 60 years old! Because it is an old vessel, there were only poor quality or no spare parts available. The owner faced leakage, high service costs and heavy engine vibration.

CHANGING THE SHIP DESIGN

Idea Marine, a Swedish firm specializing in power measurements of ship propulsion, carefully studied the existing design and took all possible measurements before proposing an entirely new solution. The owner and Idea Marine examined the whole system thoroughly and together, they challenged the proposed design to make sure it was going to work. To illustrate the significance a bit more: the old engine was 24 tonnes and 600 brake horsepower; the new engine is 2 tonnes and 1400 horsepower. Imagine the impact this has on the ship design.

WORKING TOGETHER

Idea Marine and the owner worked closely together. For the sealing systems, Lagersmit helped to ensure the right sealing solution was used so the seals would meet the tough working and environmental challenges on the vessel.

Ola explains: “We controlled the whole system, from the engine to the propeller. We also calculated the impact on the ship design and made alterations to the vessel. That way, there’s only one party responsible for the redesign. This is how Idea delivers peace of mind to its customers”

DETAILS ABOUT THE RETROFIT

The stern tube and one bearing were kept in place. The retrofit involved:

Mitsubishi engineZF gearbox

Specially-designed propeller from Idea

New shaft

New seals by Lagersmit

New flexible couplings

The whole design was tailored to suit this particular ship, including the placing of concrete in the hull of the vessel to guarantee the correct stability.

FINISHING THE PROJECT

The project took two years from scratch in 2013. In 2014 the design was settled; delivery took place in 2015. Refitting was done in a local shipyard, Docksta.

The hull of the vessel is now perfect, very well kept and might be able to last another 60 years. The vessel has doubled his missions since this retrofit! The owner is really happy with this project.