Whether it’s a dredge operation or an industrial water process, work goes on – day and night, worldwide. To minimise the risk of sudden pump failure, it’s important to predict the lifetime of your pump shaft seal. In this blog we share how you can measure the lifetime in a manual and digital way.

Condition monitoring enables you to keep track of your pump seal’s performance and plan maintenance in time, enabling a predictable lifetime and minimising the risk of for example sudden failures. You can measure your seal’s performance in different ways, ranging from a simple manual operation with a bucket and timer to a completely automated approach with a programmable logic controller (PLC).

Manual condition monitoring

If you want to manually monitor the seal’s condition, all you need is a bucket and stopwatch. The water from the Liquidyne® is eventually transported from the pump side to the drain side of the seal. At this point, you can use a bucket to collect the drain flow for a period of time (like 60 seconds) and record how much water you collected. Our specialists are often asked exactly what you should take notice of when checking the condition of the seal. Most important is to measure the following within fixed time intervals:

- Water inflow and outflow (litres/hour)

- Temperature difference between inflowing and outflowing water

Digital flow meter

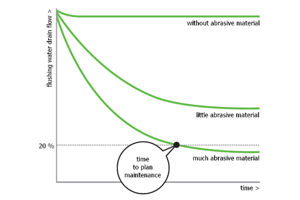

A digital flow meter is used to measure the rate of flow of liquids, in this case water. For Liquidyne pumping applications, Lagersmit offers a range of approved, fully digital flow meters. By installing the non-mechanical flow meter in a pipeline from the pump, the flow is logged without disrupting the flow. The data can be logged locally at the pump site or, if you have a more advanced approach, in your data management system (PLC). If logged, you will see a similar graph to the figure above.

The state of the grooved bush is measured based on the flow. Due to the wear of the grooves on the grooved bush, the flow decreases over time. The lip seal will also have more contact with the running surface and allows less water to be transported over the bush. The water flow towards the drain decreases, and as a result the drain flow decreases.

Recording the drain flow from the moment the seal was taken into use allows for maintenance to be scheduled more efficiently and the maintenance interval to be maximised. When the drain flow is at 20% of the initial drain flow, you can plan maintenance. The most advanced way to monitor the condition of your seal is to connect the digital flow meter to a PLC.

Suitable for which Liquidyne seals?

The Liquidyne 3-stage is used as an example, but the digital flow meter can be applied on all Liquidyne seals. This means you can apply the flow meters on Liquidynes for dredge pumps, industrial (cooling) water or other pumps, jet pumps, gland pumps, and process pumps.

Contact

In the world of pumps, we want people to feel safe, secure and empowered, so you can drive your operation to the limit and beyond with Peace of Mind. Do you want to know more about how the Liquidyne can add value to your (pump) operation? Contact our expert Eric de Paauw!