Have you come across Gard's recent study on stern tube damage? It reminded us of our 2020 blog exploring the effects of Environmentally Acceptable Lubricants (EAL) on stern tube bearings. Read the 2020 blog here.

In this blog, we'll break down Gard's study findings, shedding light on the main points and sharing our perspective.

- Over 700 Claims in a Decade

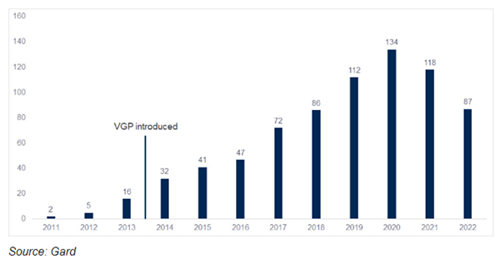

Gard has handled over 700 claims related to shaft and stern tubes in the last decade alone. The graph below provides an overview with the cases totaling more than USD 5,000. This raises concerns and prompts us to delve into the reasons behind this surge.

- Claims Spike After VGP Introduction

In 2019, DNV GL conducted a study with Scandinavian Insurers (Gard, Skuld, Swedish Club & Norwegian Hull Club) and identified two key differences between EALs and traditional mineral oils:

- EALs have lower viscosity under pressure compared to mineral oils, reducing the safety margin during peak loads on the bearing's aft part.

- EALs exhibit lower viscosity at lower temperatures, impacting safety during cold starts and mooring trials.

Traditional mineral oil outperforms EALs due to its robust lubricating oil film, consistent performance with water, and excellent seal compatibility.

- Root Cause Analysis

Gard's analysis reveals that 80% of incidents investigated involve stern tube seals' failure with EAL oil. These incidents predominantly occur in vessels with an average age of 12 years.

Gard offers valuable advice to shipowners, including choosing the right EAL viscosity, frequent oil sample testing, continuous bearing temperature monitoring, and careful monitoring of aft seal oil circulation.

Find some of Gard’s advices below. You may click the link below this blog to read the whole article.

During Vessel’s operation

- Choose the right EAL viscosity. Consider the qualities of EALs available in the market to minimize the risk of failure.

- Frequent testing of representative oil samples

- Continuous monitoring of bearings’ temperature

- Close monitoring of aft seal oil circulation.

- If you use air-type seals, you should frequently monitor the drain tank.

During routine repairs / new buildings

- Air-type seals are preferred together with use of traditional mineral oil

- Modify aft seal oil system to the continuous circulation type rather than the static / gravity type

- Consider installing a net pickup ring and a rope cutter. This can prevent ropes and fishing nets from entering the stern tube seal area.

Lagersmit’s Perspective

At Lagersmit, we stock EAL seals but advise caution. If switching to EAL is unavoidable, consider the viscosity grade carefully. Assess the impact of the originally recommended mineral oil on shaft vibrations, ensuring the EAL oil can provide similar performance.

Alternatively, air- or void-type seals can be used to comply with VGP/VIDA while sticking to mineral oils. Our Supreme Ventus® offers a solution, allowing you to navigate American waters with mineral oils and avoiding the issues highlighted by DNV GL.

Conclusion and Contact

Summing up, the blog highlights the concerning rise in stern tube-related claims and offers insights from Gard's study. If you have questions or want to explore solutions, contact our team. We're here to assist with new builds, maintenance, or retrofit applications.

Link to Gard’s study: https://www.gard.no/web/articles?documentId=36102314.